The Ultimate DTF Printing Overview: Strategies, Products, and Applications

The Ultimate DTF Printing Overview: Strategies, Products, and Applications

Blog Article

From Principle to Development: Releasing Imagination With DTF Printing on Various Fabrics

In today's dynamic realm of fabric design, the application of Straight to Movie (DTF) printing modern technology has actually reinvented the process of moving elaborate layouts onto different fabrics. The blend of advancement and artistry with DTF printing opens doors to a realm where imagination recognizes no bounds.

Checking Out the Conveniences of DTF Printing

One essential advantage of DTF printing is its versatility in terms of the materials it can be used to. Unlike some typical methods that are limited to particular material kinds, DTF printing can be made use of on a large variety of products, consisting of cotton, polyester, blends, and also natural leather.

Additionally, DTF printing supplies outstanding resilience, making it suitable for generating durable layouts on textiles - DTF Printing. The prints developed through DTF are known for their vibrant colors and resistance to fading, cracking, or peeling - making certain that the final product maintains its quality also after numerous cleans or prolonged usage. This toughness makes DTF publishing an economical option for makers seeking to produce top notch, enduring styles on textiles

Creating With DTF: Advice

Designing effectively with DTF printing entails understanding the complexities of digital layout software and understanding how to maximize styles for the very best outcomes on different textiles. When developing styles for DTF printing, it is essential to take into consideration the material color, texture, and type to ensure that the end product satisfies expectations. Right here are some pointers and methods to boost your DTF style process:

Resolution is Key: Begin with high-resolution images to maintain clearness and sharpness in your styles. Low-resolution pictures can cause a pixelated end product.

Shade Matching: Take note of shade accuracy when designing for DTF printing. Use shade management devices to guarantee that the shades in your design equate properly onto the fabric.

Vector Videos: Utilize vector graphics anywhere feasible to keep the quality of your styles when scaling them to different dimensions. (DTF Printing)

Examination Prints: Constantly conduct test prints on example textiles to check the colors, resolution, and total design quality before major manufacturing.

Selecting the Right Fabrics for DTF

When taking into consideration the optimal fabrics for DTF printing, the option of product plays a crucial duty in achieving the desired top quality and longevity of the final printed designs. Choosing the right material is essential for guaranteeing that the colors adhere well, the design stays sharp and lively, and the total look fulfills assumptions. Fabrics with a high polyester content are usually preferred for DTF printing due to their capability to hold the ink well and create dazzling prints. Polyester blends can additionally function properly, supplying an equilibrium in between longevity and print top quality. Additionally, textiles with a smooth appearance often tend to produce far better results as they supply a regular surface area for printing, enabling for accurate detailing and color precision. It is very important to take into consideration the desired use the printed fabric when picking the material, as different fabrics supply differing levels of washability, stretch, and breathability. By very carefully selecting the right textile for DTF printing, designers can enhance the long life and aesthetic impact of their styles.

Step-by-Step DTF Printing Refine

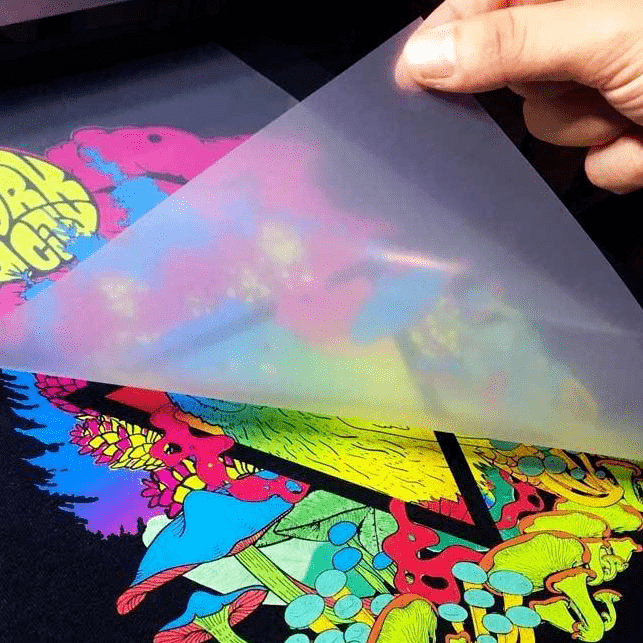

After treating, the website here published style is after that moved onto the material making use of a warmth press. The transfer procedure requires cautious placement to make certain that the style is used accurately. As soon as the transfer visit is total, the textile is allowed to cool before the transfer film is peeled off, leaving behind the dynamic and resilient layout on the textile. Ultimately, the material might go through post-processing treatments to boost the design's longevity and vibrancy, resulting in a top notch end product on-line or display.

Showcasing DTF Masterpieces

Have you ever before admired the elaborate details and vivid colors of DTF masterpieces showcased on numerous materials? DTF printing has changed the method designs are moved onto textiles, enabling unparalleled precision and richness in shades. When these DTF masterpieces are placed on display, they astound audiences with their striking visuals and meticulous craftsmanship.

Among the most exciting elements of showcasing DTF work of arts is the adaptability it offers. Whether it's a attractive and vibrant design on a tee shirt, a detailed pattern on a pillow case, or a custom print on a canvas bag, DTF printing permits limitless opportunities. This flexibility allows designers and artists to unleash their creative thinking and bring their visions to life on a large range of fabrics.

Furthermore, the durability of DTF prints makes certain that these masterpieces can endure the test of time without shedding their vibrancy. Whether presented in galleries, worn as trendy garments, or used as ornamental accents in homes, DTF work of arts proceed to excite audiences with their phenomenal high quality and visual charm.

Conclusion

In final thought, DTF printing provides a flexible and ingenious approach for letting loose creative thinking on numerous textiles. By discovering the advantages of DTF printing, creating with certain ideas and techniques, choosing suitable fabrics, and following a detailed printing procedure, musicians can click now showcase their masterpieces effortlessly. This process permits for the smooth transition from concept to creation, providing countless opportunities for innovative expression.

In today's dynamic realm of textile layout, the usage of Straight to Movie (DTF) printing modern technology has transformed the process of transferring detailed styles onto various fabrics.Creating efficiently with DTF printing involves understanding the ins and outs of digital layout software program and comprehending how to maximize styles for the best results on different materials.When considering the optimum materials for DTF printing, the choice of product plays an important duty in accomplishing the preferred top quality and longevity of the final published designs. The next step is publishing the design onto an unique DTF transfer film making use of a DTF printer with the suitable ink. By exploring the advantages of DTF printing, designing with specific suggestions and tricks, choosing ideal textiles, and adhering to a step-by-step printing procedure, artists can showcase their work of arts with simplicity.

Report this page